Induction Bend

Business Areas

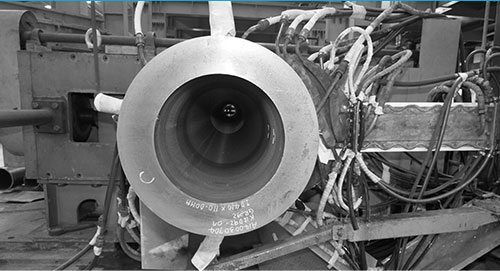

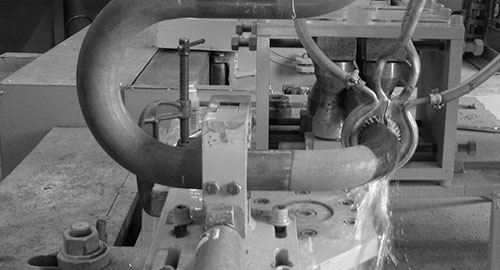

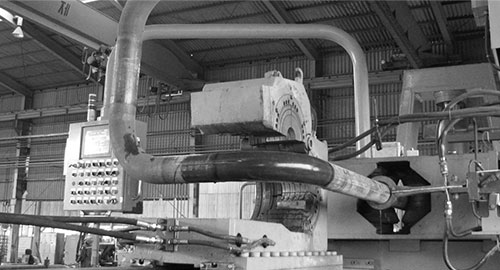

SUNG IL (SIM) is performing induction bend that is a part of shop fabricated piping

as an independent business. We manufacture and supply induction bend through

induction bending that can be applied to 1.5DR small radius.

-

-

Quality

Quality- Quality soundness is improved (due to decrease of quantities of welds by substitution a elbow)

- Excellent mechanical properties (such as fatigue, tensile, elongation better than raw material due to TMT(Thermal-Mechanical Treatment) and phase transformation effect during high frequency induction pipe bending)

- Solve the non-uniformed quality (by decreasing of skillful welder)

-

Design

Design- Unessential change of design (Induction bend can be applied instead of elbow without changing the design)

- Easy to design (there is no restriction in size, thickness, bending radius and angles)

- Possible production of various types (including 3D Bending and coil bending)

-

-

-

Cost

Cost- Decrease a cost for quality control and assurance (Inspection, Insevice, NDE cost saving)

- Decrease for operating cost (a demanded Inservice inspection welds are decreased)

- Decrease a cost for material control (due to decrease fitting to be applied to fabrication)

-

Period

Period- Shorten Manufacturing Period

(due to simplification of process) - Shorten Construction Period

(due to reduced welding process)

- Shorten Manufacturing Period

-